-40%

3M 300LSE 9495LE Double Sided Transparent Clear Adhesive Tape, Cellphone Repair

$ 3.66

- Description

- Size Guide

Description

3M 300LSE9495LE

Super Sticky Clear

Double Sided Adhesive Tape

for

Glass, HSE & LSE Plastics, Metals and Cell phone repair

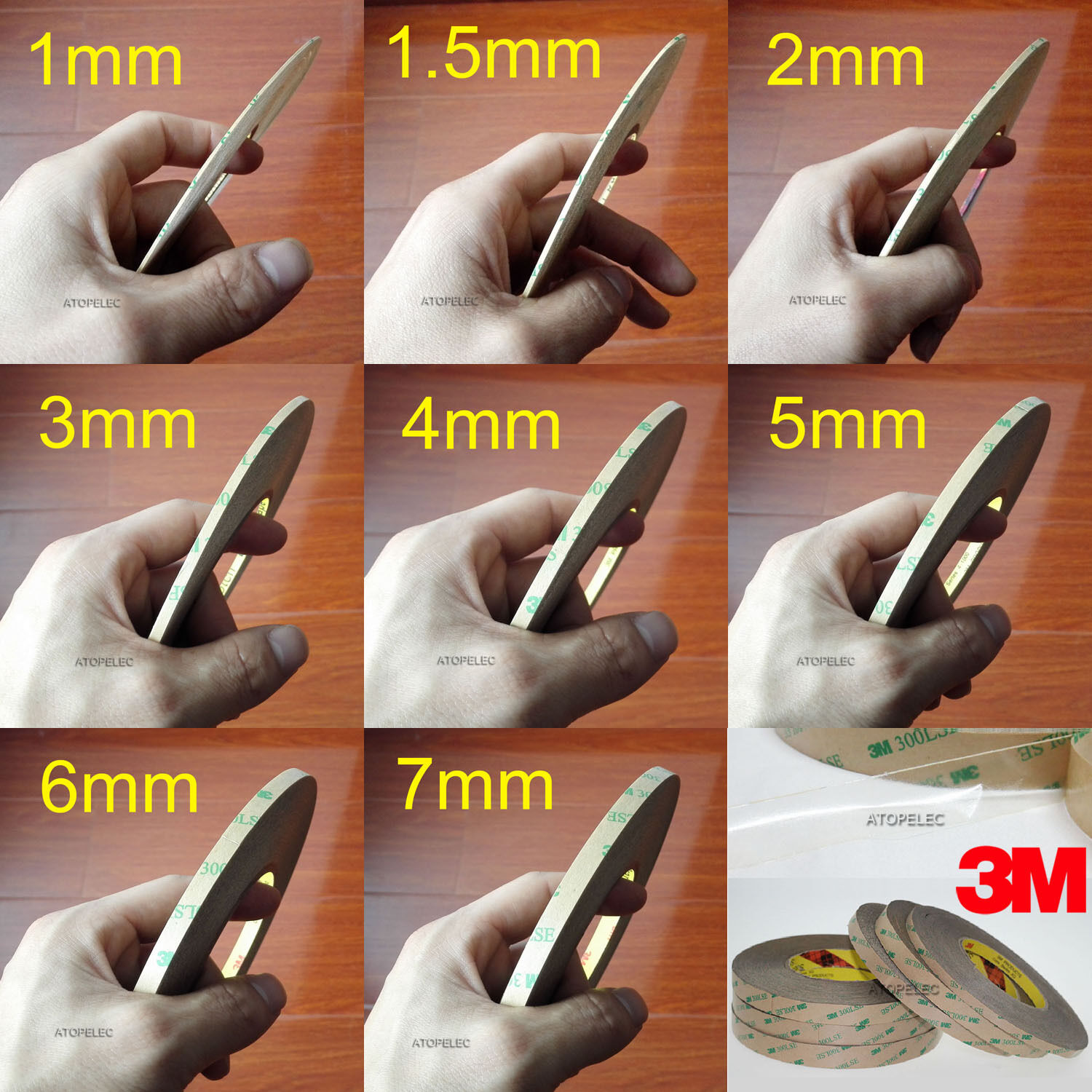

Available Width and Length:

1.5mm - approx. 1/16" (pack of 2 tapes 18m length each),

2mm -

approx.

5/64"(1 tape 27m length),

3mm -

approx.

1/8" (1 tape 27m length),

4mm -

approx.

5/32" (1 tape 55m length),

5mm -

approx.

3/16" (1 tape 55m length),

6mm -

approx.

1/4" (1 tape 55m length)

7mm -

approx.

9/32" (1 tape 55m length),

8mm -

approx.

1/3" (1 tape 55m length),

9mm -

approx.

23/64" (1 tape 55m length),

10mm -

approx.

3/8" (1 tape 55m length),

11mm -

approx.

7/16" (1 tape 55m length),

12mm -

approx.

1/2" (1 tape 55m length)

25mm -

approx.

1" (1 tape 55m length)

Applications:

Battery Bonding, Battery Door Attachment, Bezel Bonding, Camera Module Assembly, Case Assembly, Cover Lens Bonding, Display Bonding, Electrical Insulation Bonding, Electronic Component Bonding, Logo Bonding, Low Surface Energy Bonding, Memory Card Bonding, Module Bonding to PET Card, Rubber Feet Bonding, Speaker Module Assembly, Touch Panel Bonding, Touchpad Assembly, Touchpad Bracket Assembly

Specifications:

Color:

Clear

Operating Temperature Range (Celsius):

93 - 149 Degrees C

Total Tape Thickness without Liner:

0.17 mm (

6.7 mil)

Substrates:

Glass, HSE Plastics, LSE Plastics, Metals

Application Techniques:

Bond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure and moderate heat, from 100°F (38°C) to 130°F (54°C), will assist the adhesive in developing intimate contact with the bonding surface. To obtain optimum adhesion, the bonding surfaces must be clean, dry and well unified. Some typical surface cleaning solvents are isopropyl alcohol or heptane.* Ideal tape application temperature range is 70°F to 100°F (21°C to 38°C). Initial tape application to surfaces at temperatures below 50°F (10°C) is not recommended because the adhesive becomes too firm to adhere readily. However, once properly applied, low temperature holding is generally satisfactory.

Environmental Performance:

Humidity Resistance:

High humidity has minimal effect on adhesive performance. No significant reduction in bond strength is observed after exposure for seven days at 90°F (32°C) and 90% relative humidity.

UV Resistance:

When properly applied, nameplates and decorative trim parts are not adversely affected by exposure to direct sunlight.

Water Resistance:

Immersion in water has no appreciable effect on the bond strength. After 100 hours at room temperature, the high bond strength is maintained.

Temperature Cycling Resistance:

High bond strength is maintained after cycling four times through: 4 hours at 158°F (70°C) 4 hours at -20°F (-29°C) 4 hours at 73°F (22°C)

Chemical Resistance:

When properly applied, nameplate and decorative trim parts will hold securely after exposure to numerous chemicals including oil, mild acids and alkalis.